Services

Founded in a garage with just one mill and one lathe, Boyens has grown significantly, now operating 11 CNC machines to meet customer demand. Founder Kevin Boyens, who also taught machining as an adjunct instructor at a local community college for five years, has led the company which now has over 100 years of combined experience across the team. With the slogan “Boyens Machine is here for you,” the company continues to build strong partnerships and deliver dependable, high-performance machining solutions.

experience

Boyens Machining has proudly served a variety of clients across industries, including Freund/Vector Corp. (tablet press components), Oral B (engineering redesigned parts), Lloyd Table Co. (hydraulic table components), Fusion Tech (meat and dairy processing parts), Innerduct Corp. (aluminum couplers), and the University of Iowa's Engineering and Hydrology Department. Our versatility and precision make us a trusted partner in both industrial and research applications.

precision

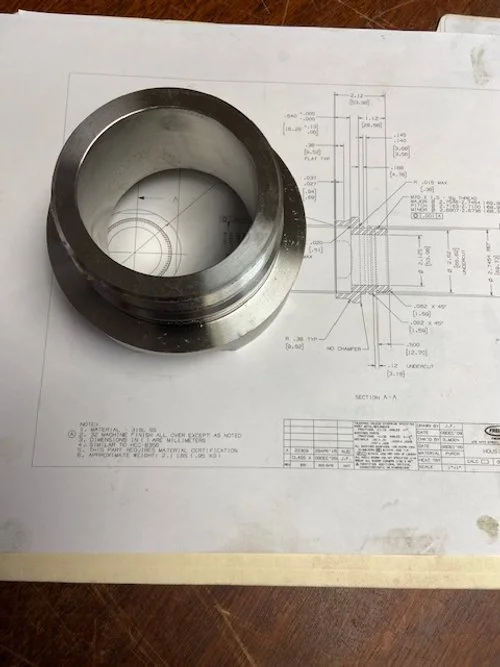

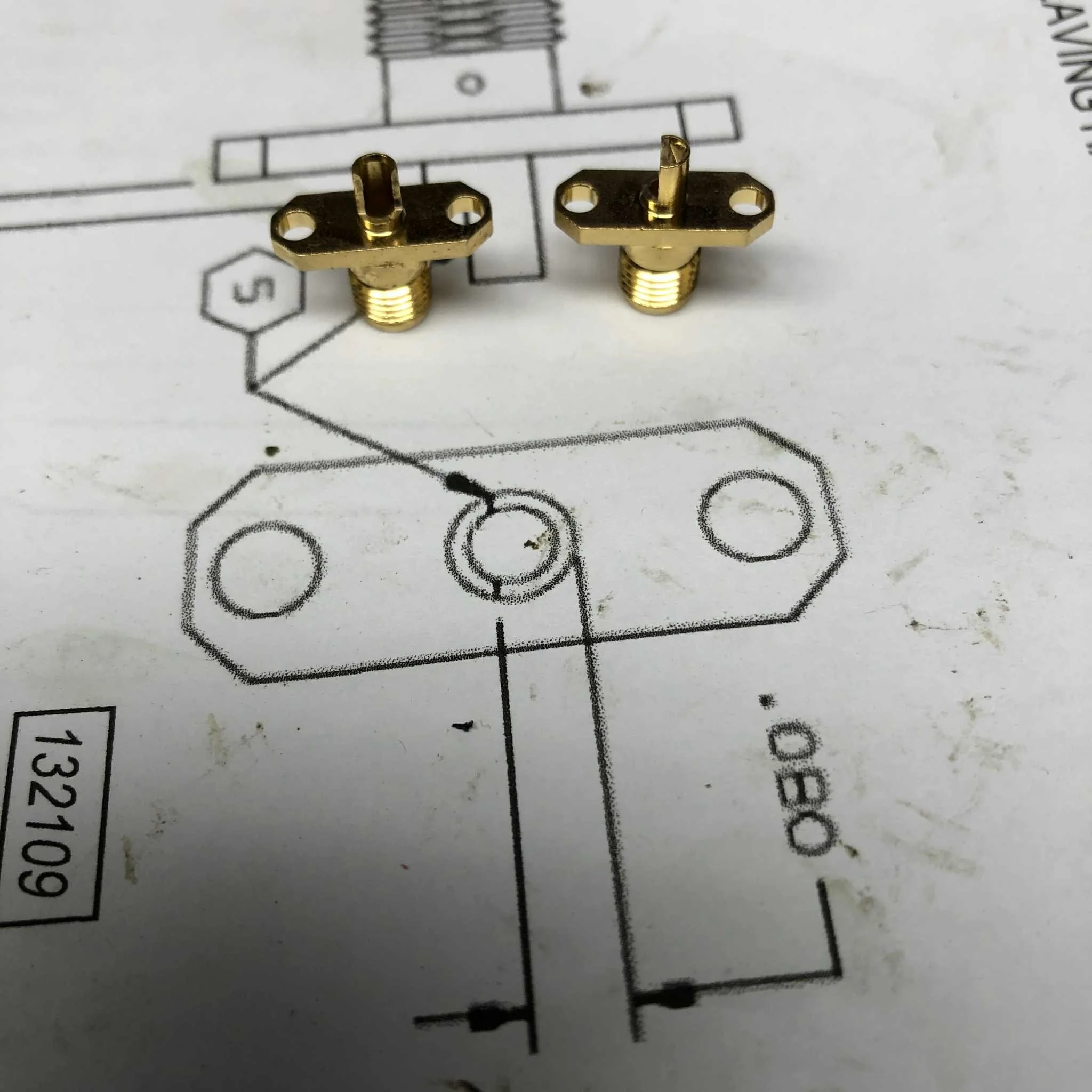

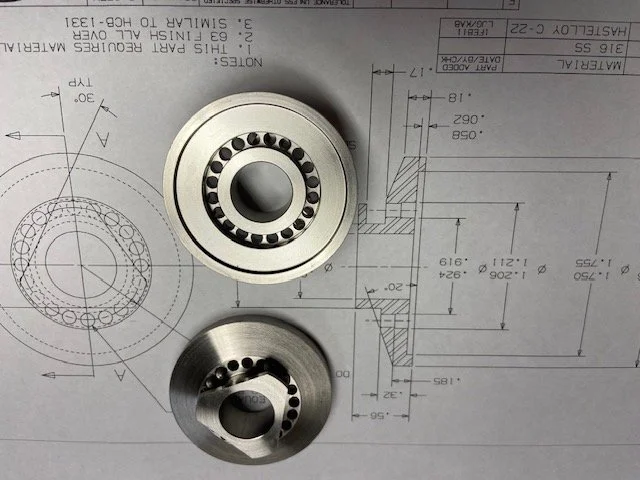

with over 20 years in the industry, we specialize in manufacturing high-quality stainless steel parts for the personal healthcare, pharmaceutical, and meat processing sectors. We are staffed by a team of expert machinists, most with over 30 years of hands-on manufacturing experience. Utilizing the latest CNC milling and turning technology, We ensure precision and tight tolerances on every job, and are capable of polishing stainless steel from 2BOS up to an 8S sanitary mirror finish.

Quality

We at Boyens machine a wide range of materials, including plastics like UHMW, Delrin, Teflon, and acrylic, as well as metals such as carbon steel, aluminum, brass, bronze, copper, high nickel alloys, and various stainless steel grades including Inconel and Hastelloy. Our capabilities include turning parts from 18" in diameter up to 60" in length, and milling up to 64" of material. We also offer OEM fabrication and manufacture components that are then assembled by our clients into complete products then distributed nationwide.